Epoxy Grouting Singapore

Epoxy grout services involve the installation, repair, or maintenance of grout made from epoxy resin. Epoxy grout is a type of grout that is durable, resistant to stains, chemicals, and water, making it ideal for use in areas prone to moisture, such as kitchens, bathrooms, and swimming pools.

Here are some common services provided by epoxy grout professionals:

- Installation: Epoxy grout installation involves mixing the epoxy resin with a hardener and filler, then applying it between tiles or other surfaces. Proper installation ensures a strong, durable bond between tiles and prevents water penetration

- Repair: Epoxy grout may crack, chip, or become discolored over time. Epoxy grout repair services involve removing damaged grout and replacing it with new epoxy grout to restore the integrity and appearance of the tiled surface.

- Sealing: While epoxy grout is naturally resistant to stains and water, sealing it can provide an extra layer of protection and enhance its longevity. Epoxy grout sealing services involve applying a sealant to the grout lines to prevent moisture and dirt from penetrating the grout.

- Cleaning and Maintenance: Regular cleaning and maintenance are essential for preserving the appearance and durability of epoxy grout. Epoxy grout service providers may offer cleaning services using specialized cleaners and equipment to remove dirt, grime, and stains from grout lines without damaging the epoxy resin.

- Consultation and Inspection: Professionals in epoxy grout services may also provide consultation and inspection services to assess the condition of existing grout, recommend appropriate repair or maintenance measures, and provide guidance on proper care and cleaning to homeowners or property managers.

When hiring an epoxy grout service provider, it's essential to choose a reputable and experienced company with a track record of quality workmanship. Additionally, inquire about warranties, pricing, and any specific requirements or recommendations for your particular project.

Epoxy grouting process:

The epoxy grouting process involves several steps to ensure proper installation and long-lasting results. Here's a general overview of the epoxy grouting process:

- Surface Preparation: Ensure that the surface to be grouted is clean, dry, and free of any debris, dust, or contaminants. Proper surface preparation is crucial for achieving a strong bond with the epoxy grout.

- Mixing Epoxy Grout: Epoxy grout typically comes in two parts: resin and hardener. Follow the manufacturer's instructions to mix the epoxy resin and hardener thoroughly. It's essential to mix the components in the correct ratio to ensure proper curing and performance.

- Application: Use a rubber grout float or a grout bag to apply the mixed epoxy grout onto the tiled surface. Press the grout firmly into the joints, ensuring complete coverage and filling of all gaps between tiles.

- Tooling: After applying the epoxy grout, use a grout float or a grout tool to smooth and level the grout lines. This step helps ensure a uniform appearance and removes any excess grout from the tile surface.

- Cleaning: Allow the epoxy grout to set for a specific period as recommended by the manufacturer. Once the grout reaches the appropriate hardness, use a damp sponge to clean off any excess grout residue from the tile surface. Be careful not to disturb the grout lines while cleaning.

- Curing: Epoxy grout requires adequate time to cure and reach its full strength. Follow the manufacturer's instructions regarding the curing time, which typically ranges from 24 to 72 hours. During this period, avoid walking on or disturbing the freshly grouted surface.

- Sealing (Optional): While epoxy grout is inherently stain-resistant and waterproof, sealing it can provide an additional layer of protection against stains and moisture infiltration. If desired, apply a suitable epoxy grout sealer according to the manufacturer's instructions after the grout has fully cured.

- Final Inspection: Once the epoxy grout has cured and any sealer has been applied, inspect the grouted surface for any imperfections, such as cracks, voids, or discoloration. Touch up any areas as needed to ensure a flawless finish.

Following these steps meticulously can help ensure a successful epoxy grouting process and a durable, attractive tiled surface.

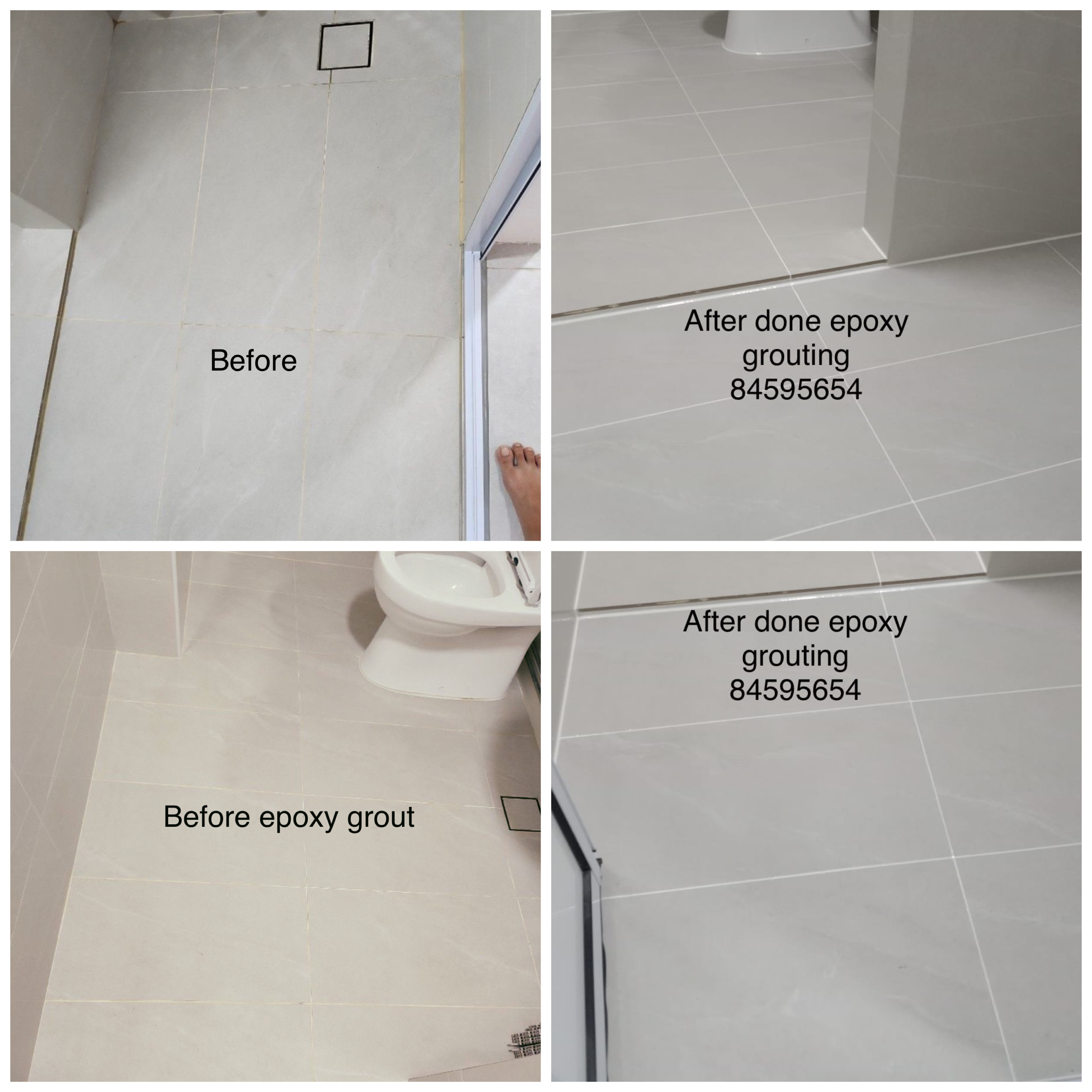

Before start for cleaning tiles. After cleaning n epoxy grouting service done.

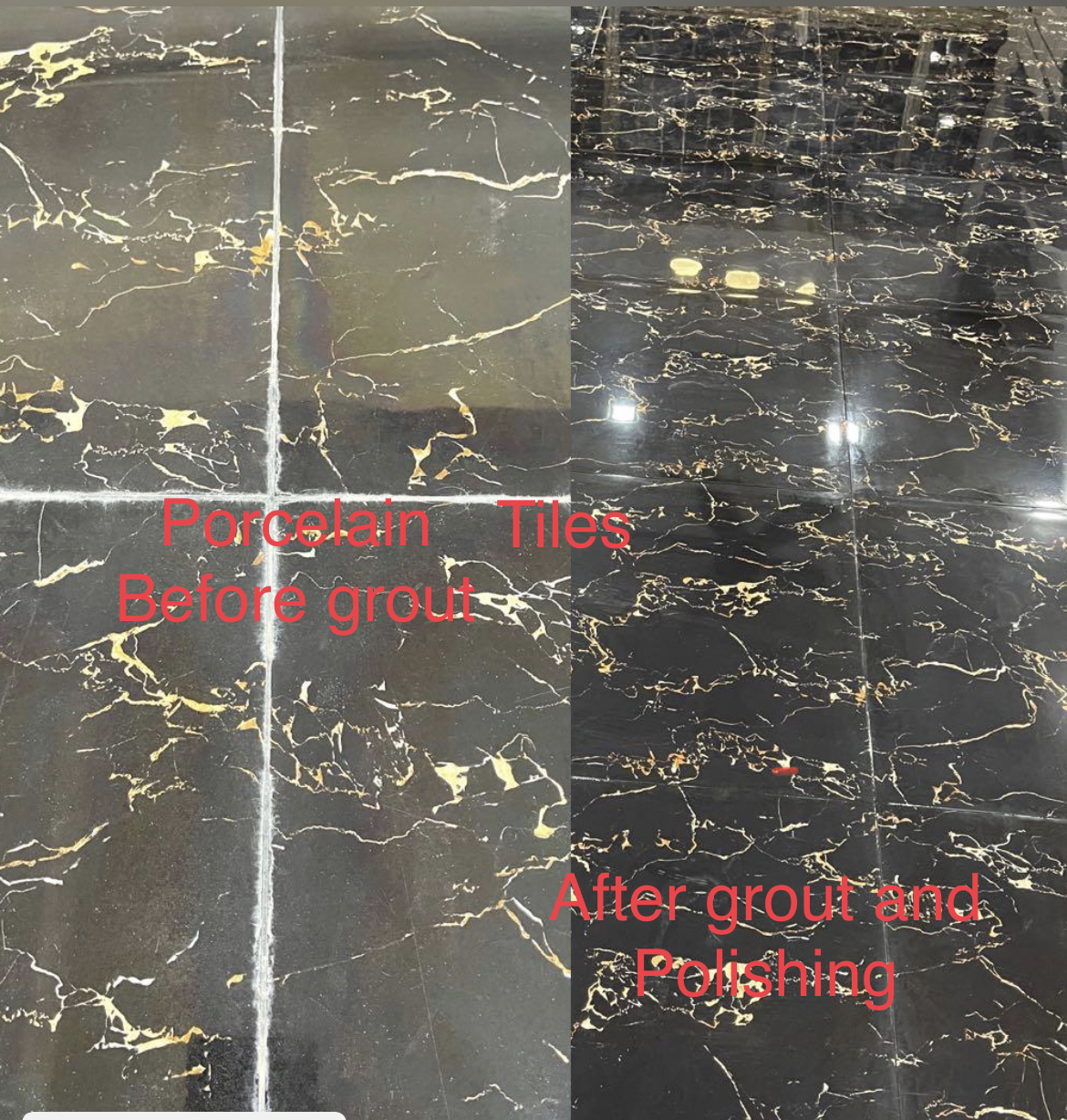

Porcelain Tiles before grout. After grout and polishing service done.

Before clean and polish tiles and before epoxy grout. After done epoxy grouting on tiles.

Before polish or cleaning tiles. After epoxy grouting and polishing tiles done.

Advantages of Epoxy Grouting:

Epoxy grouting offers several advantages compared to traditional cement-based grouting:

- Durability: Epoxy grout is highly durable and resistant to stains, chemicals, water, and cracking. It can withstand heavy foot traffic and is less prone to deterioration over time, making it ideal for high-traffic areas like kitchens, bathrooms, and commercial spaces.

- Stain Resistance: Epoxy grout is inherently resistant to stains from food, beverages, and other common household substances. Its non-porous nature prevents liquids and contaminants from penetrating the grout, making cleanup easier and reducing the risk of discoloration.

- Waterproofing: Epoxy grout forms a waterproof barrier when properly installed, preventing moisture from seeping into the substrate and causing damage to underlying materials. This makes it suitable for use in wet environments such as showers, swimming pools, and outdoor patios.

- Chemical Resistance: Epoxy grout is resistant to a wide range of chemicals, including harsh cleaning agents, acids, and alkalis. This makes it suitable for use in industrial settings, laboratories, and commercial kitchens where exposure to chemicals is common.

- Color Consistency: Epoxy grout maintains its color consistency over time, unlike cement-based grout which may darken or discolor with age and exposure to sunlight. This ensures a uniform appearance across the tiled surface and reduces the need for frequent maintenance and resealing.

- Flexibility: Epoxy grout has a degree of flexibility that allows it to withstand minor substrate movement without cracking or crumbling. This flexibility helps maintain the integrity of the tiled surface, especially in areas prone to temperature fluctuations or structural settling.

- Low Porosity: Epoxy grout has low porosity, which means it does not absorb water or harbor bacteria, mold, or mildew. This makes it hygienic and easy to clean, reducing the risk of bacterial growth and odors in areas like kitchens and bathrooms.

- Longevity: Due to its superior durability and resistance to wear and tear, epoxy grout typically has a longer lifespan than cement-based grout. This can result in cost savings over time by reducing the need for frequent repairs and replacements.

Overall, epoxy grouting offers numerous benefits in terms of durability, aesthetics, and maintenance, making it a popular choice for a wide range of residential, commercial, and industrial applications.

After epoxy grouting floor tiles looks like shiny and new tiles.

After epoxy grouting on floor and walls look likes shiny.

After epoxy grouting and polishing on floor and walls look likes shiny.

Epoxy grouting and polishing done on floor and walls look likes shiny.

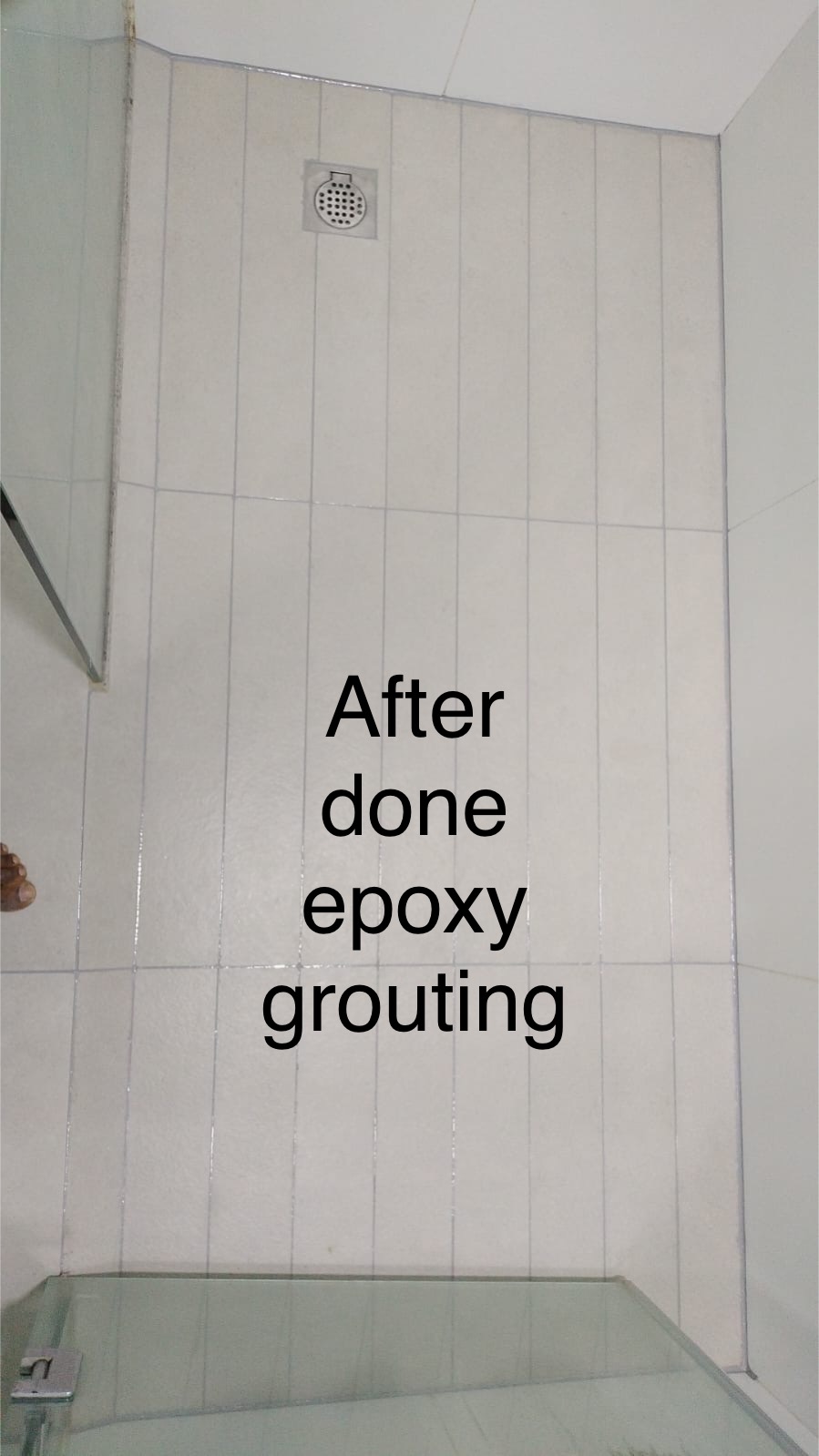

After epoxy grouting on wall tiles looks like shiny and gorgeous.

After epoxy grouting done on floor view.

After epoxy re-grout and it looks like in good shape and shiny.

Epoxy grouting and polishing done on floor and walls look likes shiny.

Exceptional work is a shining example of dedication and excellence in epoxy grouting service

If you're looking for a grouting solution for marble tiles, you might consider options such as epoxy grout or sanded grout, depending on your specific needs and preferences. Epoxy grout offers high durability and stain resistance, while sanded grout is suitable for filling wider grout joints and providing a textured finish.

We provide best epoxy grouting service in Singapore area. if need any epoxy related service in singapore area then we are here to help you to provide best epoxy service to your door.

We ae professional for epoxy grouting service and we have specialist, skilled, experienced worker for any kind of epoxy grouting related task in Singapore.

We Support 24/7 support to customer and response for epoxy grouting service query.

Please call 📱 for more information about any kind of marble polish,clean,finish or gum grouting

service.

Phone : +65 8459 5654

WhatsApp : +65 8459 5654

Frequently Asked Question

You May Ask

Epoxies that have hardened without modification may be fragile. For two-part epoxy to cure properly, precise mix ratios are needed. slow healing periods.